Synopsis

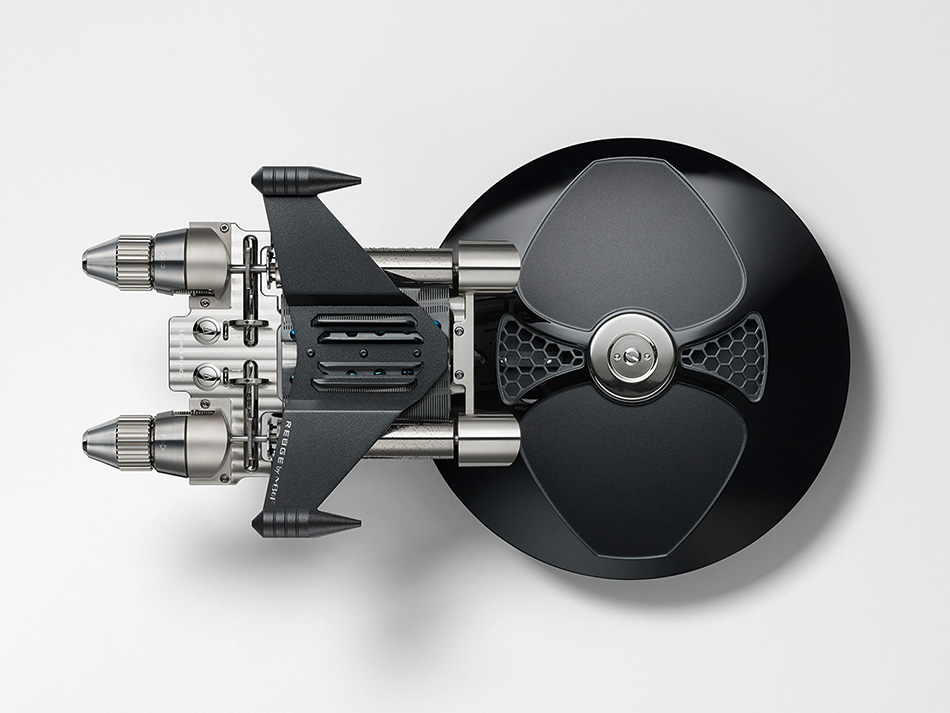

With its spaceship-like design, rock and sci-fi melodies and innovative resonance soundboard, MusicMachine 2 (MM2) boldly goes where no music box has gone before. Underneath its futuristic guise, MM2 features all the traditional elements of a beautifully-crafted, high-end music box. That’s no surprise as it’s made by REUGE, the music box manufacturer with nearly 150 years of expertise and experience.

MusicMachine 2 doesn’t just look unconventional; it plays unconventional melodies as well: Themes from Star Wars, The Empire Strikes Back and Star Trek, on one ‘channel’; Led Zeppelin’s Stairway to Heaven, The Rolling Stones’ Angie and The Clash’s Should I Stay or Should I Go? on the other. Small wonder: MM2 was conceived and designed by MB&F and its songs have been selected by their rock ‘n’ roll founder and sci-fi fan, Maximilian Büsser.

MusicMachine 2 is powered by two independent movements mounted on the starship’s tail section. Each movement has its own winding key (disguised as a propulsion thruster), mainspring barrel, horizontal cylinder (looking like a nacelle tube) with pins, and comb with hand-tuned teeth sounding each note. The cylinders play three melodies each. An air regulator in the form of a circular fan (resembling a radar) governs the unwinding speed of the cylinder.

If MusicMachine 2 looks out of this world, then just wait until you hear it. One of the biggest challenges was in amplifying the sound. In traditional music boxes, the movement is placed in contact with a walnut wood casing that helps to augment the volume. But MusicMachine 2 is anything but traditional. Its sound-emitting case – a shallowly domed aluminium shell forming the main hull – is ostensibly separate from the movement mounted on the tail section. The diagonal tail boom is the only discernible link between the two. So how is sound energy on MM2 beamed from A to B? Thanks to an ingenious solution developed by Jeanmichel Capt of JMC Lutherie, that’s how.

A stringed instrument maker by trade, Capt has developed a highly scientific approach to the luthier’s craft to produce devices harnessing the acoustic properties of 350-year-old spruce wood. Only one in 10,000 spruce trees have the exceptional acoustic properties required. Selected trees are cut down in November when sap flow is minimal and the timber is then dried for five to ten years.

For MusicMachine 2, Capt created a bespoke soundboard featuring Nomex® – a type of honeycomb-structured Kevlar – sandwiched between two resonant-spruce membranes. This circular sandwich ‘floats’ on silent rubber blocs inside the main hull, the resonance dome.

Through the Nomex® honeycomb runs a rigid carbon-fibre bar connecting to the ship’s tailboom, which is fixed to the mainplate. The melodious vibrations generated by the two movements are conducted down the tail boom, along the carbon bar, through the Nomex® honeycomb and across the surface of the 350-year-old spruce membranes. Capt even engineered the movements’ mainplate to isolate the combs to minimise sound energy loss and maximise volume. The result is a clear, loud, pure sound, supremely rich in timbre.

Following on from the first MusicMachine, launched in 2013 and featuring a streamlined space shuttle design, MM2 is the second instalment in what will be a memorable trilogy of MusicMachines. REUGE CEO Kurt Kupper says: “Star Wars, Star Trek, Alien… Sci-fi classics have spectacular sequels and MusicMachines are no different. MusicMachine 2 is a veritable blockbuster. After seeing it, after hearing it, you are unlikely to forget it very quickly.”

MusicMachine 2 is a limited edition of 33 pieces in white and 66 pieces in black.

MusicMachines – music boxes for the 25th century

Mechanical music boxes produce melodies by way of tuned teeth on a steel comb being plucked by pins on a revolving cylinder. Music box movements share many similarities with their horological counterparts: Energy derived from a coiled spring is transferred by a gear train and the unwinding speed is carefully regulated. High-end music box components are even finely finished similarly to high-end watch movements.

Since music boxes first appeared in the early 19th century, Switzerland became the hub of high-quality music box production. In 1865, Charles Reuge was a pioneer of the genre when he set up his first musical pocket-watch shop in Sainte-Croix – and 150 years later, REUGE is the only remaining manufacturer of high-end music boxes in the world.

Designed by MB&F and made by REUGE, the first MusicMachine, which featured a sleek space shuttle design, was launched at Baselworld 2013. Building on the success of this initial collaboration, REUGE and MB&F have joined forces again to create MusicMachine 2, this time completing the dream team with JMC Lutherie.

MusicMachine 2’s sci-fi design

REUGE created MusicMachine 2 based on a futuristic starship design proposed by MB&F. Working in collaboration with ECAL design graduate Xin Wang, MB&F developed a concept cleverly incorporating all the essential music box features – musically-tuned combs, pinned cylinders, winding mechanisms, mainspring barrels and regulators – and looking like an intergalactic spaceship. To optimise the sound created by MusicMachine 2, Jeanmichel Capt of JMC Lutherie developed MM2’s ingenious internal soundboard.

The melodies

MusicMachine 2 doesn’t just look like something from a science fiction movie: Three of the melodies have been taken directly from sci-fi classics. On the left cylinder, MusicMachine 2 is armed with the theme from ‘Star Trek’ by Jerry Goldsmith, the theme from ‘Star Wars’ by John Williams and ‘Imperial March’ from ‘The Empire Strikes Back’, also by John Williams.

MB&F’s Horological Machines are edgy and iconoclastic and this rock’n’roll attitude is neatly conjured in the three melodies contained on the right cylinder: Led Zeppelin’s rock classic Stairway to Heaven, The Rolling Stones’ soulful ballad Angie and The Clash’s iconic punk anthem Should I Stay or Should I Go?.

Maximilian Büsser says: “I wanted MusicMachine 2 to play ‘Stairway to Heaven’ and ‘Angie’ and I was looking for something with a bit more bravado to contrast with these. When Hervé Estienne, manager of the MB&F M.A.D.Gallery, suggested ‘Should I Stay or Should I Go?’ it sounded perfect. I love the idea of having an ‘80s punk rock song on a music box!”

Intriguingly, these three contemporary songs all have a woman at the heart of their lyrics. Merely a coincidence? “In no specific order, the most important people in my life are my mother, my wife and my daughter,” says Büsser. “My subconscious was probably playing tricks on me and triggered that choice of songs without my realising it!”

Mechanically recreating music

Once MB&F confirmed the melodies, a REUGE musician examined the tunes and identified the most recognisable passages from each. Work then began on recreating the music, keeping in mind that each cylinder contains three melodies. Working out these two groups of three arrangements, each one limited to 36 seconds, and the multitude of notes that these entail – some notes are used by all three melodies, some notes are exclusive to just one melody – represents a considerable technical and artistic achievement in which the musician’s instinct tops any computer.

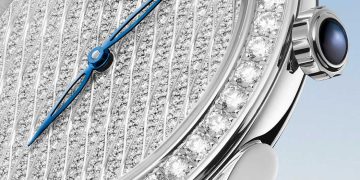

MusicMachine 2’s engine room: combs and cylinders

The music box movements – containing combs, cylinders, winding mechanisms, mainspring barrels and regulators – are fixed to the Geneva wave-decorated mainplate forming MusicMachine 2’s tail section.

The two combs lie flat opposite each other, each forming a unique pair with its cylinder and containing the bespoke selection of 72 notes. The combs are hand-tuned from a unique steel alloy selected for its acoustic impact. For bass notes, the tooth is thickened by the traditional method of adding lead. A machine then tests the frequency of each tooth and slivers of material are removed to accurately tune each note. Tiny transparent, synthetic feathers are added behind the bass note teeth, acting as dampers.

The beautifully hand-finished cylinders gleam like a pair of imposing reactors – ‘nacelle tubes’ in Star Trek speak. The cylinders essentially contain ‘the scores’ of the melodies, with as many as 1,400 precision-placed pins plucking the teeth of the comb as the cylinder revolves. The REUGE musician determines precisely where to place each pin. The pins are shaved to ensure uniformity of length and then polished.

Finally, hot resin is applied inside the cylinder, which, when hardened, rigidly fixes the pins to maximise sound quality. Once one melody is played, the cylinder moves along its long axis to align the right pins with the right teeth to play the next melody. Each melody corresponds to one complete revolution of the cylinder.

Winding keys and mainspring barrels

Resembling propulsion thrusters on each side of the tail section, the conical, grooved winding keys in nickel-plated brass are linear with the mainspring barrels and cylinders. This is an unconventional configuration for music boxes but MB&F’s daring design dictated it – it also allows a more efficient transfer of energy.

Fan regulators

In the centre of the mainplate are distinctive vertical circular panels. While these look as though they may be radar dishes to navigate an asteroid field, they are actually the cylinder speed regulators. When fully wound, the main springs have more torque so tend to turn the cylinders faster than when nearly unwound. To compensate, these circular fan air regulators provide exponentially more resistance when rotating faster than slower, allowing for a constant revolution. A similar system is found in many minute repeater watches.

MusicMachine 2’s main hull – the resonance dome and internal soundboard

While MusicMachine 2’s tail section contains the engine, the main hull serves as the ‘resonance dome’. This shell is created out of one solid block of aluminium, which is machined before receiving a finishing touch by hand. The team at JMC Lutherie were asked to develop and integrate into this resonance dome a bespoke soundboard.

JMC’s Jeanmichel Capt explains: “It was a great test for us because the music box movements were separate from the resonance dome and internal soundboard. So we had to ensure the sound energy was transmitted between the two as efficiently as possible. I had many a long night trying to come up with a way of doing that!”

Soundboard principles

“Wooden soundboards traditionally feature on stringed instruments such as violins, guitars and pianos,” says JMC Lutherie’s CEO Céline Renaud. “The board is vibrated by the strings, creating the same frequencies and all harmonics. In MusicMachine 2, it is the music box movements, rather than strings, that generate the sound energy.

“Not only does MM2’s Soundboard amplify the sound, but the presence of the resonance spruce offers warmth, roundness, power, precision and colour to the sound, which is the meaning of music.”

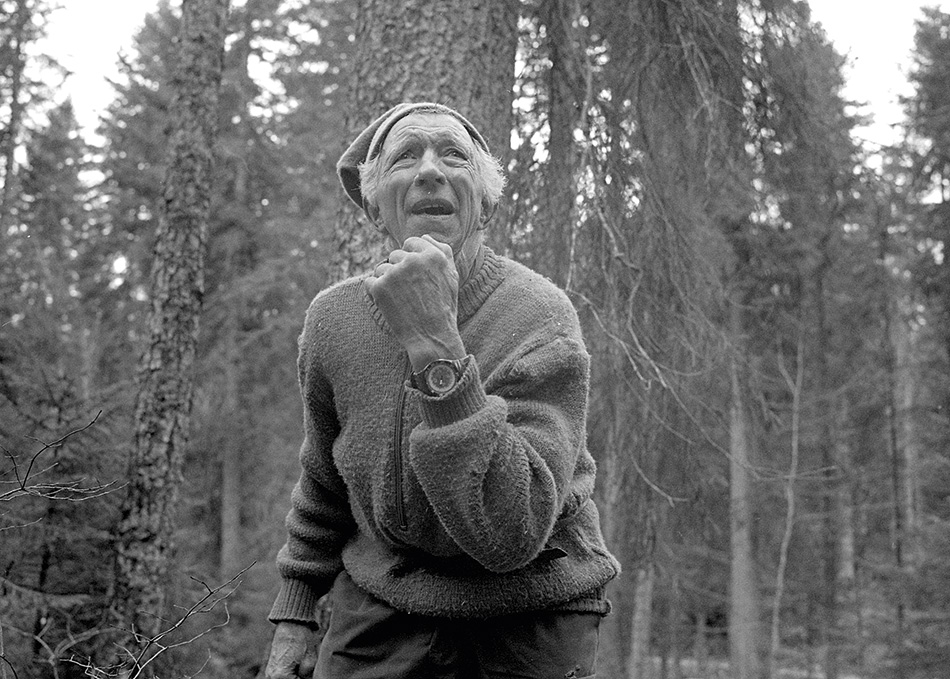

350-year-old resonance spruce wood

MusicMachine 2’s internal soundboard features two wooden membranes made from 350-year-old resonance spruce from the Risoud Forest in Switzerland, where long, cold winters and poor soil lead to slow tree growth, occasionally producing an extremely dense wood boasting superlative acoustic properties. Each resonant tree has been selected by one man, lifelong ‘tree gatherer’ Lorenzo Pellegrini. The selection process involved much observation and know-how, including hugging each trunk to see if it was straight enough to create a sufficiently resistant soundboard.

Such is the criteria for selecting appropriate wood that only one in 10,000 spruce trees is good enough to feature in a soundboard! The tree is cut down in November during a waning moon when the tree is in its driest state. The wood is left to dry for a further five to ten years and then prepared at specialist sawmills and cut into quarters. A primer is used to close the wood fibres before a non-penetrating varnish is applied.

Two soundboards in one

“Usually, to generate good frequencies and loud volume, you would increase the size of the soundboard,” says Jeanmichel Capt. “But with MusicMachine 2, we were limited by the size of the main dome, so we created a board that effectively makes the sound of two soundboards!”

To achieve this, Capt sandwiched the two spruce membranes around Nomex®, a honeycomb-structured variant of Kevlar, fixing them together with special luthier glue applied using a vacuum press and paying close attention to their thickness. “Thinner or thicker, the soundboard would not generate the same frequencies as those generated by the music box movements,” says Capt. “So we had to get the dimensions of the spruce membranes and the Nomex® just right.”

Through the centre of the honeycomb, and making full contact with the two membranes, is a solid rectangular cuboid bar made of carbon fibre that both rigidifies the board and diffuses the sound vibrations as efficiently as possible over the full surface of the spruce membranes. Part of the trick here is to place the carbon bar at a right angle to the grain of the spruce: This perpendicular configuration moves the sound energy up to 10 times more quickly across the spruce membranes, for maximum volume.

Sound-conducting tail boom

To complete the puzzle, JMC still needed to connect the soundboard to the music box movements on MusicMachine 2’s tail fin, and so, in tandem with the REUGE team, they created the specially-shaped tail boom made of aluminium, a material selected for its sound-conducting properties. JMC engineered the end of the boom so that it makes optimal contact with the carbon bar and is placed at the ‘sweet spot’ of the soundboard.

Finally, JMC also helped REUGE to isolate the zone on the mainplate from where most sound energy emanates – where the combs are fixed with heat-blued screws. This isolation enables the retention of as much sound energy as possible so it channels down the tail boom, through the carbon rod, through the Nomex® honeycomb and across the spruce of the soundboard.

While the tail boom essentially performs the function of a bridge to transmit the vibrations – just like on a guitar or a violin – the vent holes in the resonance dome act like a hole on a guitar, letting out the sound from the soundboard.

“I was dazzled when I saw the first finished MusicMachine 2, and then just blown away when I heard it,” says Maximilian Büsser. “This is the first music box of this size which is not only so loud and clear, but also works in ‘stereo’ – you can hear the melody simultaneously from the combs and from the resonance dome. Even more incredibly, it does not require a special surface to place it on – it sounds superb wherever you put it. For me, that makes a triple world premiere!”

MusicMachine 2: Technical specifications

MusicMachine 2 is a limited edition of 99 pieces:

33 pieces with white finish and 66 pieces with black finish

Dimensions and weight

Dimensions: 300mm wide x 511mm long x 168mm high

Total weight: approx. 8kg

Main hull – resonance dome

Main body: Domed shell in aluminium

Matte sections: lacquered

Gloss sections: White UV-resistant lacquer or black lacquer depending on version

Central disc on top: nickel-plated brass

Landing gear: Bead-blasted and lacquered aluminium or black depending on version

Internal soundboard by JMC Lutherie: 350 year-old resonance spruce wood membranes sandwiching a Nomex® honeycomb and carbon-fibre bar

Tail boom

Sound-conducting ‘tail boom’ in lacquered aluminium or black depending on version to transfer sound to internal soundboard

Tail section – movement and finishing

MusicMachine 2 features two 3.72 movements (3 refers to number of melodies on each cylinder; 72 refers to number of notes on each comb); one movement is ‘right’ configured; one movement is ‘left’ configured (they rotate in opposite directions)

Mainplate: nickel-plated brass, decorated with Geneva waves. The mainplate holds both movements; each movement includes a mainspring, cylinder, comb and regulator

Mainsprings: wound via conical, grooved winding keys in the form of thrusters, in nickel-plated brass

Barrels: nickel-plated brass

Regulator fans: nickel-plated brass

Cylinders: nickel-plated brass

Start/stop and repeat/continue functions

1 melody = 1 revolution of the cylinder

3 melodies per cylinder

Length of each melody: 36 seconds

Power reserve per cylinder: 15 minutes

Pins hand-applied and hand-polished

Length of pins: 1mm; diameter of pins: 0.3mm

Pins per cylinder: approx. 1,400

Combs: steel alloy and lead; 72 teeth per comb; each comb attached to nickel-plated brass vibration plate

Tail fin: Featuring winglets and central outlet grill, in lacquered aluminium or black depending on version.

Melodies

Right cylinder – extracts from: ‘Stairway to Heaven’ (1971) by Led Zeppelin; ‘Angie’ (1973) by The Rolling Stones; ‘Should I Stay Or Should I Go?’ (1981) by The Clash

Left cylinder – extracts from: ‘Star Wars’ (1977) main title by John Williams; ‘Imperial March’ (1980) by John Williams; ‘Star Trek’ (1979) main title by Jerry Goldsmith

REUGE – premier manufacturer of music boxes in the world

With nearly 150 years of expertise and experience, REUGE is positioned as the only premier producer of music boxes in the world today. While REUGE has a comprehensive collection of both classical and contemporary music boxes, the brand also prides itself on its ability to create bespoke pieces or limited series – like MusicMachines – for discerning clients. The REUGE mentality is to respect tradition, but at the same time move forward with beautiful contemporary music boxes for the 21st century.

It was in 1865 that Charles Reuge established his first musical pocket-watch shop in Sainte-Croix, Switzerland. Charles Reuge was a pioneer, managing to incorporate a musical cylinder and a miniature comb into a watch movement. His son Albert Reuge converted the family’s atelier into a small factory in 1886 and REUGE musical movements began to feature in the most unlikely of objects, including powder compacts and cigarette lighters.

Guido Reuge, who presided over the brand for much of the 20th century, built the current REUGE manufacture in Sainte-Croix in 1930 and expanded the company. In the 1960s and ‘70s, REUGE diversified, taking over the manufacture and marketing of mechanical singing birds of Bontems and Eschle and also developed the skills and capacity to create or replicate virtually any melody. Since 2006, Kurt Kupper has been CEO of REUGE. Under his guidance the brand has developed a particular ability to customise and create bespoke music boxes.

JMC Lutherie – pioneering guitar makers and creators of the Soundboard loudspeaker

Based in Le Brassus in Switzerland’s Vallée de Joux, JMC Lutherie was co-founded in 2005 by luthier Jeanmichel Capt and CEO Céline Renaud, one of the top 20 leading women in Swiss business according to Bilan magazine. JMC harnesses the incredible talents of Capt and the exceptional acoustic properties of 350-year-old resonance spruce wood sourced from the nearby Risoud Forest.

A research and teaching partner at the Swiss Federal Institute of Technology, Lausanne (EPFL) and the School of Business and Engineering Vaud (HEIG-VD), Capt is a visionary stringed instrument maker. He has taken time-honoured luthier techniques and fused them with a decidedly scientific approach exploring the audio-acoustic possibilities of resonance spruce.

It was Capt who developed JMC’s pioneering Soundboard high-fidelity loudspeaker. Launched in 2007, the Soundboard features strategically-placed transducers on a cambered spruce and Nomex® membrane to produce ultra-pure sound rich in timbre for a unique listening experience.

JMC has also used this venerable wood to create an Acoustic Docking Station loudspeaker for smartphones as well as resonance trays and cylinders for a number of big haute horlogerie brands to showcase the full auditory splendour of their minute repeater watches.

MB&F – award-winning concept laboratory

In 2005, after seven years in the senior management team of Jaeger-LeCoultre and seven years as managing director of Harry Winston Rare Timepieces in Geneva, Maximilian Büsser created the world’s first horological concept brand: MB&F – Maximilian Büsser & Friends. By working in small, hyper-creative groups composed of people Büsser enjoys working with, MB&F develops radical horological concepts, fusing traditional, high-quality watchmaking with cutting-edge technology to create three-dimensional mechanical sculptures.

In 2007, MB&F unveiled their first Horological Machine. Its sculptured, three-dimensional case and beautifully finished Engine set the standard for the idiosyncratic Machines that followed. In 2011, MB&F launched the round-cased Legacy Machine collection, more classical pieces paying tribute to 19th century watchmaking excellence by reinterpreting complications from the great horological innovators. At the Grand Prix d’Horlogerie de Genève in 2012, MB&F’s Legacy Machine No.1 was awarded the Public Prize (voted for by horology fans) and the Best Men’s Watch Prize (voted for by the jury). At the 2010 Grand Prix, MB&F won Best Concept and Design Watch for Horological Machine No.4.