Time and Power – who says you can’t have it all? Derived from the iconic HM3 series, MEGAWIND combines a giant 22k gold and titanium winding rotor with highly legible time indication cones rising up from the complex asymmetric case, like truncated gold-framed monoliths.

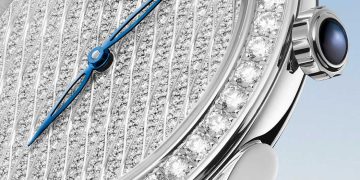

Rotating within their twin gold and sapphire crystal frustums, the cones display hours (left) and minutes (right), with the time clearly visible from both the large numbers on the sides of the cones as well as duplicate indications on their flat caps.

However, while it may be a temporal desire that attracts the viewer’s gaze towards the three-dimensional sculptures housing the hours and minutes, it is likely to be the giant battle-axe shaped winding rotor that mesmerises the eye as it swings unhurriedly, but indomitably, over the meticulously hand-finished movement.

As they revolve, the strong, but lightweight high-tech titanium arms of the rotor intermittently reveal tantalising views through to the fervently oscillating balance wheel.

Power is nothing without control and MEGAWIND offers a perfectly harmonious balance of the two.

MEGAWIND is powered by the beautifully engineered, Jean-Marc Wiederrecht-designed HM3 engine. Placing the rotor and regulator on the dial side required an inverted movement, which was only possible thanks to two large high-tech ceramic bearings – visible through the display back – that efficiently transmit time up to the revolving hour and minute cones above. Rotating domes of this size and shape posed a number of technical challenges. The hour and minute domes are machined from solid blocks of aluminium, chosen for its optimal strength to weight ratio; this reduces energy requirements to an absolute minimum.

Close inspection of the case – which comprises over 50 separate components – is rewarded with a myriad of carefully considered details, including the bevelled perimeter of the rotor display crystal that adds visual flair as the angles catch and reflect flashes of light; the bespoke clover-head gold screws; and the cleverly integrated lugs attaching the strap.

MEGAWIND is available in red gold with a 22k red gold rotor or white gold with a sky-blue 22k gold rotor.

MEGAWIND

Inspiration and Realization:

The original HM3 was developed to display the machine’s beautifully finished movement in operation and MEGAWIND follows the same principle. Harmoniously crafted bridges, rapidly oscillating balance wheel, gearing and MB&F’s iconic battle-axe automatic winding rotor are all open to view on the dial side. This allows the wearer to fully appreciate the art and craft of the HM3 engine by drawing the viewer’s gaze inside the highly complex machine; a machine comprising more than 300 fine-finished, high-precision components.

The movement of HM3 has been literally turned upside down to allow for an uninterrupted panorama of the 22k gold and titanium winding rotor’s powerfully graceful arcs and the high-speed oscillations of the balance wheel. Jean-Marc Wiederrecht, winner of the inaugural award for Best Watchmaker at the 2007 Grand Prix d’Horlogerie de Genève, was entrusted with turning the drawings and designs of Max Büsser and designer Eric Giroud into horological reality and, with his team at Agenhor, he surpassed the challenge.

Indications:

The hour and minute cones are milled from solid aluminium to paper-thin thickness. The cones are housed within three-dimensional truncated gold and sapphire crystal cones, which are brazed together. Brazing is a high-temperature soldering technique which is aesthetically pleasing and ensures a solid, water-resistant construction.

Mega Rotor:

Independent Finnish watchmaker Stepan Sarpaneva (co-creator of MB&F’s MoonMachine) provided both the initial idea for the large rotor and the name, MEGAWIND. The two 22K gold blades of the iconic MB&F battle-axe rotor on the dial make what is called a ‘mystery’ rotor because, in appearing to be symmetrically balanced instead of having a visibly off-centred mass, they look to defy the laws of physics. This ‘mystery’ is achieved by machining the underside of one of the gold blades to a razor-thin edge, so reducing its mass.

Ceramic Bearings:

Time indications are usually located on the top, or dial side, of a movement. As the movement of HM3 is inverted to display its operation, an efficient solution was needed to bring power from the bottom of the movement to the timekeeping cones at the top. Standard pinions set in jewels would have required complex, friction-generating gearing, and would require support top and bottom – a factor which would increase the height of the movement, and thus the watch.

So instead of standard jewelled pinions, HM3 features two large-diameter (15mm) high-tech ceramic bearings. Because of their large diameter, these bearings minimise the number of friction inducing gears and, due to the rigidity resulting from their ultra-high precision design and manufacture, they only require support at one end (the base) so allow for a thinner movement.

MEGAWIND – Technical Specifications

Movement:

Three-dimensional horological engine designed by Jean-Marc Wiederrecht / Agenhor; Sowind oscillator and gear train

Balance oscillating at 28,800 bph

Automatic winding rotor in 3 parts: hub in titanium with outer sections in 22K gold, fastened with 4 rivets

Time indications transmitted via ceramic ball bearings

Number of jewels: 36 (all functional)

Number of components: 270

Functions:

Hours on one cone

Minutes on second cone

Case:

Available in 18k white gold/titanium or 18k red gold/titanium

Screwed-down crown

Dimensions (exclusive of crown and lugs): 47mm x 50mm x 17mm

Number of case components: 52

Sapphire crystals:

Sapphire cones and front and back display crystals have anti-reflective treatment on both faces

Strap & Buckle:

Black hand-stitched alligator with 18k gold and titanium custom designed folding buckle.

‘Friends’ responsible for MEGAWIND

Concept: Maximilian Büsser / MB&F

Product Design: Eric Giroud / Eric Giroud Design Studio

Technical and Production Management: Serge Kriknoff / MB&F

R&D: Guillaume Thévenin / MB&F

Movement Development: Jean-Marc Wiederrecht and Nicolas Stalder of Agenhor

Movement manufacturing: Georges Auer / Mecawatch

Movement base: Stefano Macaluso, Raphael Ackermann and Steve Sturchio of Sowind

Rotor: Denis Villars / Cendres + Métaux Galétan SA

Ceramic ball bearings: Patrice Parietti / MPS

Movement assemblage: Didier Dumas, Georges Veisy, Alexandre Bonnet and Bertrand Sagorin-Querol of MB&F

Case and buckle construction and production: Philippe Marti, Dominique Mainier and Bertrand Jeunet of G.F.Châtelain

Sapphire cones: Jean-Michel Pellaton and Gérard Guerne / Bloesch SA

Dials: François Bernhard and Denis Parel of Nateber

Strap: Olivier Purnot / Camille Fournet

Presentation case: Isabelle Vaudaux / Vaudaux, Frédéric Legendre / Lekoni

Production logistics: David Lamy / MB&F

Marketing communications: Charris Yadigaroglou, Virginie Meylan and Eléonor Picciotto of MB&F

M.A.D.Gallery: Hervé Estienne / MB&F

Sales: Alexandre David and Patricia Duvillard of MB&F

Graphic design: Gérald Moulière and Anthony Franklin of GVA Studio

Product photography: Maarten van der Ende

Portrait photography: Régis Golay / Federal

Website: Stéphane Balet and Guillaume Schmitz of Sumo Interactive

Texts: Ian Skellern / underthedial

MB&F – The Genesis of a Concept Laboratory

The projects that gave Maximilian Büsser the most pleasure and personal satisfaction during his fifteen years managing prestigious watch brands were those working with talented independent watchmakers. An idea for his own personal utopia emerged: that of creating a company dedicated solely to designing and crafting small series of radical concept watches in collaboration with talented professionals he both respected and enjoyed working with. The entrepreneur in Büsser brought the idea to reality.

MB&F is not a watch brand, it is an artistic and micro-engineering concept laboratory in which collectives of independent horological professionals are assembled each year to design and craft radical Horological Machines. Respecting tradition without being shackled by it enables MB&F to act as a catalyst in fusing traditional, high-quality watchmaking with cutting-edge technology and avant-garde three-dimensional sculpture.

MB&F’s first timepiece, HM1 (Horological Machine No1) was delivered from 2007 and introduced the concept of three-dimensional architectural horology. This was followed by HM2 in 2008 and HM3 in 2009, both inspired by science fiction. The year 2010 heralded the HM4 Thunderbolt, considered by many to be MB&F’s most audacious machine to date. In 2011 Legacy Machine No1 heralded the introduction of a new traditionally-inspired line. The supercar-inspired HM5 ‘On the Road Again’ was presented in 2012.

Biography– Maximilian Büsser

Maximilian Büsser was born in Milan, Italy, before moving at an early age to Lausanne, Switzerland where he spent his youth. Growing up in a multi-cultural environment and family – his father was a Swiss diplomat who met his mother, an Indian national, in Bombay – led Büsser to develop a cross-cultural, broad-based approach to life and to business.

In July 2005, at the age of 38, Büsser created the world’s first horological concept brand: MB&F (Maximilian Büsser & Friends), in which he is now partnered with Serge Kriknoff. Büsser’s dream with MB&F is to have his own brand dedicated to developing radical horological concepts by working in small, hyper-creative groups composed of people he enjoys working with.

Entrepreneurship is Maximilian Büsser’s forte. In 1998, when only 31, he was appointed Managing Director of Harry Winston Rare Timepieces in Geneva. During his seven years there Büsser developed the company into a fully-fledged and well respected haute horlogerie brand by developing the strategy, products, marketing and worldwide distribution, whilst integrating design, R&D and manufacturing in-house. The results were a 900 per cent increase in turnover and the positioning of Harry Winston as one of the leaders in this very competitive segment.

Maximilian Büsser’s love for high-end horology was nurtured by his first employer, Jaeger-LeCoultre. During his seven years in the senior management team during the 1990s, JLC strongly increased its profile and multiplied its turnover by a factor of ten. Büsser’s responsibilities at Jaeger-LeCoultre ranged from Product Management & Development to Sales & Marketing for Europe.

Büsser graduated in 1991 with a Masters in Microtechnology Engineering from the Swiss Federal Institute of Technology, Lausanne.