Magnetism, shock and gravity have virtually no effect on TAG Heuer’s revolutionary new oscillator, which features a tailor-made balance wheel and a hairspring made of a new material developed in-house by the innovative Swiss watchmaker.

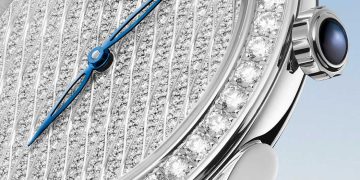

La Chaux-de-Fonds, Switzerland – August 2019: During the Geneva watch fair earlier this year, TAG Heuer unveiled an innovation – one that demonstrated its commitment to developing technology that explores uncharted realms of watchmaking. The new technology, called Isograph, is an oscillatory regulator with a carbon-composite hairspring and tailor-made balance wheel that improves accuracy and timekeeping performance, particularly with regard to environmental interference. The technology is integrated into the TAG Heuer Carrera Calibre Heuer 02T Tourbillon Nanograph and the new TAG Heuer Autavia collection, and will be found in more TAG Heuer watches in the future.

Born of the necessity to overcome the challenges posed to metal and silicon hairsprings – shock, magnetism and gravity – TAG Heuer’s Isograph technology is produced through a highly innovative manufacturing process developed in-house by the TAG Heuer Institute. The oscillatory regulator uses a carbon-composite hairspring, a completely new material created by the Institute, and a tailor-made balance wheel.

Together, the carbon-composite hairspring and tailor-made balance wheel form the oscillatory regulator. This technology has been given the name Isograph – the trademarked name comes from the Greek words iso, meaning “equal”, and grapho, which means “to write”, referring to the stable and consistent movement of the component.

Describing the importance of this technology, Guy Sémon, CEO of the TAG Heuer Institute, said: “The development of this world first has taken years and its purpose is to improve the performance and accuracy of mechanical watches. Isograph technology is an innovation with significant importance because of the benefits it offers the wearer, and because it leads TAG Heuer into an area of avant-garde watchmaking that has yet to be uncovered and explored. It is a major achievement in the world of horology and we are thrilled to make this advanced technology available to TAG Heuer fans and watch aficionados who want their timepiece to exhibit impeccable performance and reliability wherever they go.”

A new generation of hairsprings

Known as the heart of the mechanical watch, the hairspring is the most difficult part to produce as its minute tolerances directly impact the overall accuracy of a timepiece. A team of TAG Heuer mathematicians, physicists and chemists are behind the creation of this reinvented hairspring. Usually, just a small proportion of Swiss watches are certified as chronometers. In the case of the new material that TAG Heuer has developed specifically for the hairspring, 100% of the production material is of certifiable quality, which is a clear advantage over conventional hairsprings.

Key benefits of TAG Heuer’s Isograph technology:

The lightweight hairspring is virtually unaffected by gravity and shock due to its high strength-to-density ratio and its purely elastic behaviour.

- The carbon-composite hairspring is completely antimagnetic, which eliminates the issue of inaccuracy after a watch comes into contact with a magnetic source.

- Resistance to temperature fluctuations has been achieved by pairing the carbon-composite hairspring with a tailor-made balance wheel.

- Accuracy is improved thanks to perfect concentric oscillations as a result of the carbon-composite hairspring’s design.

- This accuracy is maintained no matter how the watch is worn, held or stored. Typically, a watch’s timekeeping performance will be affected by whether it is held horizontally or vertically. Due to its low density, the carbon-composite hairspring can significantly improve this phenomenon.

- The carbon-composite hairspring is produced with the collet already attached; usually, this small part, which attaches the metallic hairspring to the balance wheel axis, requires complicated assembly and increases the risk of further inaccuracy.

In-house production for in-house technology

Starting from scratch in 2015, the team at the TAG Heuer Institute set about exploring materials and processes that could make their idea a reality.

The process began in the heart of TAG Heuer HQ, in the Swiss watchmaker’s own laboratory in La Chaux-de-Fonds. The result is a technology with exactly the right properties to improve the performance and accuracy of a watch equipped with a carbon-composite hairspring and tailor-made balance wheel. The carbon-composite hairspring is impossible to counterfeit without knowing the exact chemical formula and production process. There are only two machines in the world that are able to produce these hairsprings, and both are located in TAG Heuer’s in-house laboratory.

A look inside the TAG Heuer Institute

The TAG Heuer Institute is responsible for the development and production of Isograph technology. Guy Sémon, CEO of the TAG Heuer Institute, describes the Institute as a tool that can be used by the avant-garde watchmaker to develop advanced technologies that are the result of out-of-the-box thinking. The laboratory focuses on creating new watchmaking technologies that incorporate techniques, discoveries and science from industries outside the world of horology. The TAG Heuer Institute is made up of 30 scientists representing 11 nationalities. The young team of mathematicians, physicists, chemists and nanotechnology specialists hold degrees from some of the world’s top universities.

Reflecting TAG Heuer’s legacy of avant-garde watchmaking, Isograph technology is a revolution in horology. In the future, it will be found in timepieces across the brand’s collections for men and women. Harnessing the innovative power of the TAG Heuer Institute, the unconventional Swiss watchmaker will continue to pursue advancements that improve the performance of the stylish mechanical watches that bear the iconic TAG Heuer shield on their dials.

About TAG Heuer

In 1860, at the age of 20, Edouard Heuer founded his watchmaker’s workshop in the Jura Mountains of Switzerland. Creating the Mikrograph in 1916, sponsoring Formula 1 teams in the 1970s or launching the first luxury connected watch in 2015 are just a few examples of the major technical innovations, ultimate accuracy and passion for disruptive design that define our unique spirit. Headquartered in La Chaux-de-Fonds, TAG Heuer operates in four production sites – mastering the whole watchmaking process – and is represented on all continents through 4,500 points of sale, including 170 TAG Heuer boutiques that are now directly available on www.tagheuer.com in selected countries. TAG Heuer timepieces are designed for those who love challenges. Our influence is enhanced by our unique communication based on three pillars: sport, lifestyle and heritage, embodying our legacy and DNA. Our partnerships and ambassadors illustrate our open-minded and open-door culture, with the most prestigious and avant-garde names teaming up with TAG Heuer: the Red Bull Racing Formula One team, the Formula 1 Monaco Grand Prix, the Formula E championship, the biggest football leagues in Europe, the Americas and Asia, Manchester United, trendsetter Cara Delevingne, and actors Chris Hemsworth and Patrick Dempsey.

#DontCrackUnderPressure is much more than just a claim – it’s a state of mind. Find out more at www.tagheuer.com

Instagram: @tagheuer, Twitter: @TAGHeuer, Facebook: www.facebook.com/TAGHeuer

Downloads

All press material can be obtained free of charge at https://presscorner.tagheuer.com/directlogin

For further information, please contact:

Sonja Hagmann, International PR Manager

Tel. +41 32 919 81 52

Mobile: +41 79 898 54 73

E-mail: sonja.hagmann@tagheuer.com