‘Performance Art’ illuminated by smouldering rage

Creativity comes from a multitude of sources, but for ‘Black Badger’ founder James Thompson the fount of his creativity was rage – a rebellious fire was lit when he felt brushed aside as a student by what he perceived as an unfair administrative decision. Like MB&F, Thompson is an outsider doing his utmost to buck the system.

And he is fighting his creative corner with the most unlikely of weapons: luminescent material. Thompson mills three-dimensional objects from solid light!

More than a decade on from a perceived injustice, Thompson’s rage smoulders on in the form of vividly glowing lume. As he recounts, “It wasn’t that I had tried and failed, it was being brushed aside like crumbs on a table. Here we are 12 years later and I’m still angry about it!”

For the Performance Art collection, Thompson has reinterpreted two MB&F Machines: HMX, first launched in 2015 for MB&F’s 10th Anniversary, and Starfleet Machine, MB&F’s first table clock, which was created with L’Epée 1839.

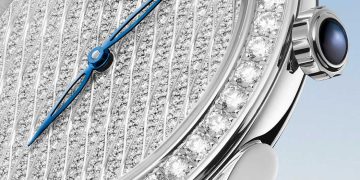

For HMX Black Badger, Thompson redesigned the “rocker cover” of HMX’s Engine, visible under the supercar-like sapphire crystal cover, milled from his signature solid blocks of brightly coloured, high-efficiency lume.

While the colours – Radar Green, Phantom Blue, and Purple Reign – are eye-catching by day, it’s when the sun goes down that they really come out to party. The long-lasting glow emitted by the high efficiency lume irradiates the HMX Engine compartment in an ethereal bath of light.

HMX displays bi-directional jumping hours and trailing minutes. Light streaming through the transparent Engine cover both illuminates the top of HMX’s Engine by day, and by night the brightly glowing lume provides its own colourful backlight to the time display.

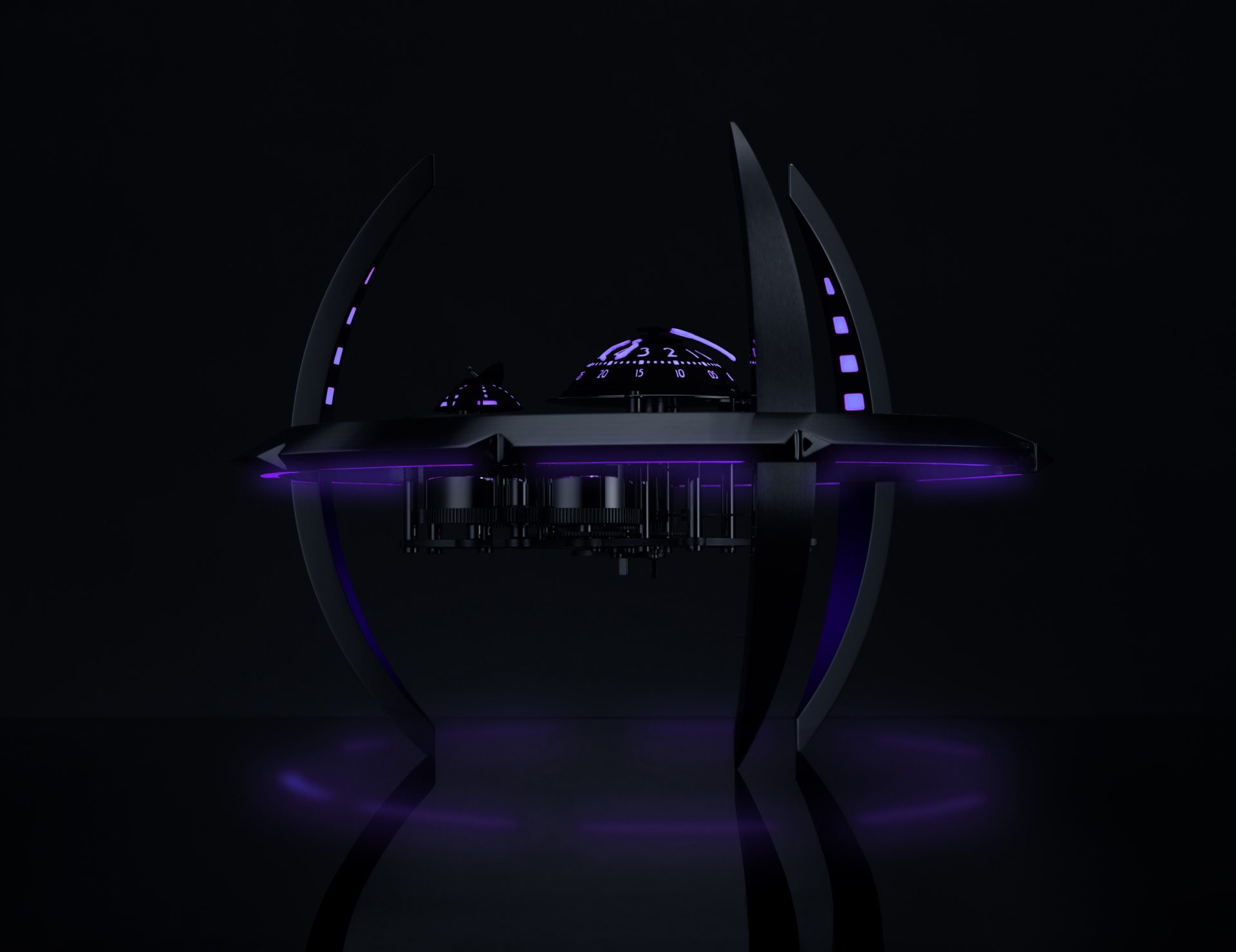

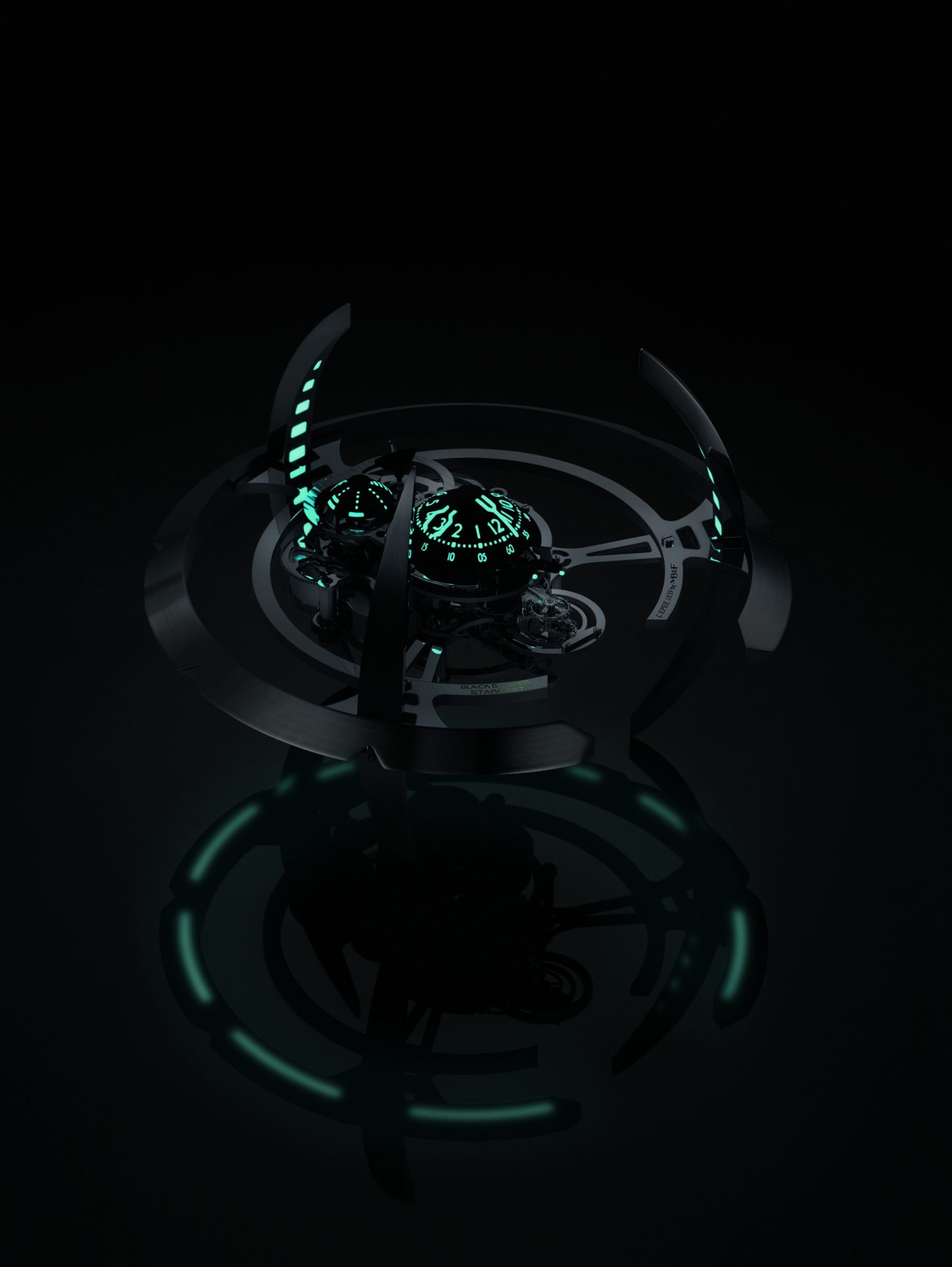

For Starfleet Machine Black Badger, Thompson added his exclusive lume under the external ring running around the Starfleet Machine movement, to the inside of the spaceship’s landing legs, and the indication domes and hands. The Black Badger touch ensures that Starfleet Machine looks just as good by night as it does by day.

While it may look like a model spaceship, Starfleet Machine Black Badger is actually a high precision clock with a 40-day power reserve that was created by L’Epée 1839 from a design by MB&F.

HMX Black Badger is a limited edition of 3 x 18 pieces in grade 5 titanium and stainless steel, with lume in Radar Green, Phantom Blue, or Purple Reign.

Starfleet Machine Black Badger is a limited edition of 3 x 18 pieces in palladium-plated brass, with lume in Radar Green, Phantom Blue, or Purple Reign.

Black Badger lume and the composition and energy of light

While most watch enthusiasts are likely to be familiar with lume in the form of Super-LumiNova-enhanced hands and markers, that substance is quite different to the luminous material exclusive to Black Badger. While Super-LumiNova is a liquid that is applied to surfaces and dries, Black Badger’s lume comes in solid blocks that are milled by hand or machine into the desired shape. Not only is Black Badger’s lume extremely efficient at storing and releasing light, being solid means that there is usually more of it, so that it shines brighter for longer.

“White” light, which includes sunlight, is actually composed of red, green, and blue wavelengths of light. There are also other wavelengths of light outside our visible range, including infrared, a red that is just beyond visible, and ultraviolet, which is a blue that is just beyond visible. These different colours or frequencies of light contain varying levels of energy, with red/infrared at the lower end of the energy scale and blue/ultraviolet at the upper end.

When charging luminous material from white light, most of the energy comes from the more energetic ultraviolet end of the spectrum. But as ultraviolet is only a small fraction of white light source emitted by most torches and sunlight, only a small fraction of the power of the light source will actually charge the lume. An ultraviolet light, on the other hand, will charge lume much more quickly because it is all high-energy light, so more energy is absorbed by the lume more quickly.

This effect means that while normal white light sources will more easily charge the Black Badger Radar Green and Phantom Blue colours, an ultraviolet light is needed to charge the Purple Reign lume because it absorbs more energy.

HMX Black Badger

Technical specifications

Limited edition of 3 x 18 pieces in grade 5 titanium and stainless steel, with lume in Radar Green, Phantom Blue, or Purple Reign

Engine:

Three-dimensional horological Engine composed of a jumping hour and trailing minutes module developed in-house by MB&F, powered by a Sellita gear train

Mechanical movement, automatic winding

22K gold automatic winding rotor

Power reserve: 42 hours

Balance frequency: 28,800bph / 4Hz

Number of components: 223

Number of jewels: 29

Functions/indications:

Bi-directional jumping hours and trailing minutes, displayed by dual reflective sapphire crystal prisms with integrated magnifying lens. Engine “rocker covers” from milled blocks of high-efficiency lume

Case:

Grade 5 titanium and stainless steel

Dimensions: 46.8 x 44.3 x 20.7 mm

Number of components: 44

Water resistance: 30m / 90’/ 3atm

Sapphire crystals:

Sapphire crystals on top, front and display back treated with anti-reflective coating on both sides

Dual reflective sapphire crystal prisms with integrated magnifying lens

Strap & buckle:

Partially perforated calfskin strap with colour complementary to Engine, titanium tang buckle

Starfleet Machine Black Badger

Technical specifications

Limited edition of 3 x 18 pieces in palladium-plated brass, with lume in Radar Green, Phantom Blue, or Purple Reign

Display

Hours and minutes: curved, hand-polished hands rotate to indicate hours and minutes on a polished, central dome. The lume-enhanced dome features MB&F’s signature numerals

Retrograde seconds: 20-second intervals indicated by double retrograde fly-out cannons emanating from central dome

Power reserve indicator: a lume-enhanced dome indicator framed by a hand-finished arc provides an intuitive view of remaining energy as it turns 270°: 5 bars, 4 bars, 3 bars, 2 bars, 1 bar (1 bar = 8 days). Complemented by a ‘radar dish’ that also revolves 270°

Lume: the solid Black Badger luminescent material is on the underside of the external ring surrounding the whole structure, on the inside of the three legs supporting Starfleet Machine, and on the hour and minute hands and dome as well as the power reserve dome

Main structure

Height: approx. 21cm

Diameter: approx. 29cm

Inner C-shaped structure, external C-shaped structure, support arcs and screws all in palladium-plated brass.

Movement

L’Epée 1839 in-house designed and manufactured movement

Balance frequency: 18,000 bph / 2.5Hz

Barrels: 5 in series

Power reserve: 40 days

Jewels: 48

Incabloc shock protection system

Manual-winding: double-ended key to set time and wind movement

Mechanism and main plate in palladium-treated brass

Transparent ‘biosphere’ dome

Material: polished glass

Height: 27cm

Maximum diameter: 31.5cm

‘Friends’ responsible for HMX Black Badger

Concept: Maximilian Büsser / MB&F

Product design: Eric Giroud / Through the Looking Glass

Development and production management: Serge Kriknoff / MB&F

Luminous components: James Thompson / Black Badger

R&D: Guillaume Thévenin and Ruben Martinez / MB&F

Movement base: Andreas Deubzer / Sellita Watch Co SA

Additional module in-house machining: Alain Lemarchand / MB&F

Case: Fabien Chapatte and Ricardo Pescante / Les Artisans Boîtiers SA

Movement parts: Alain Pellet / Elefil and Benjamin Signoud / AMECAP

Wheels: Dominique Guye / DMP Horlogerie SA

Profile-turning of small parts: Sébastien Paroz / Swissmec SA

Chrome functional oil caps: Yves Bandi / Bandi SA

Hand-finishing of movement components: Jacques-Adrien Rochat and Denis Garcia / C.-L. Rochat and Aurora Amaral Moreira / Panova

Movement assemblage: Didier Dumas, Georges Veisy, Anne Guiter and Emmanuel Maitre / MB&F

After-sales service: Didier Dumas / MB&F

Quality Control: Cyril Fallet / MB&F

Sapphire glass: Martin Stettler / Stettler Sapphire AG

Hour and minute disks: Jean-Michel Pellaton and Gérard Guerne / Bloesch SA

Crown : Jean-Pierre Cassard / Cheval Frères SA

Winding rotor: Denis Villars / Cendres + Métaux Galétan SA

Buckle construction and production: Dominique Mainier and Bertrand Jeunet / G&F Châtelain

Strap: Tristan Guyotjeannin / Creations Perrin

Presentation case: Olivier Berthon / ATS Atelier Luxe

Production logistics: David Lamy and Isabel Ortega / MB&F

Marketing & Communication: Charris Yadigaroglou, Virginie Meylan and Juliette Duru / MB&F

M.A.D.Gallery: Hervé Estienne / MB&F

Sales: Luis André, Patricia Duvillard and Philip Ogle / MB&F

Graphic design: Samuel Pasquier / MB&F, Adrien Schulz and Gilles Bondallaz / Z+Z

Product photography: Maarten van der Ende

Portrait photography: Régis Golay / Federal

Website: Stéphane Balet and Victor Rodriguez

Texts: Ian Skellern / Underthedial

James Thompson – “Black Badger”

James Thompson was born in 1976 in Ottawa, Canada and grew up in Vancouver. He studied industrial design at college, but did not graduate due to a disconnect between the courses on offer and his own interests. In 2002, this led him to apply successfully for a master’s degree course in industrial design in Lund, Sweden. Unfortunately at the time – but beneficial in the longer term! – Thompson was ejected from his master’s program after 18 months due to an administrative change in treating international students. This being “brushed aside” through no fault of his own generated a sense of rage and injustice that largely motivated his later success.

Within a year of losing his place on the master’s program and with a substantial chip on his shoulder because of that, Thompson created his own design studio called Black Badger Advanced Composites. The name derived from the fact that the badger will not back down no matter how much larger and stronger its adversary, and the fact that he was working with black carbon fibre. A logo consisting of a badger’s paw and piratical crossed bones bear testimony to his mood at the time.

“Black Badger started from a place of being p*ssed off, lonely, depressed, and abandoned and just wanting to fight anybody. It wasn’t that I had tried and failed, it was being brushed aside like crumbs on a table. I started Black Badger basically to raise a middle finger at those trying to hold me back. And here we are 12 years later and I’m still angry about it!”

Thompson moved to Gothenburg in 2008 to complete his master’s degree at the HDK design school at Gothenburg University. In 2009, Thompson started creating jewellery using solid blocks of lume, carbon fibre, and titanium – and discovered that he had created a new market. In 2010 he completed his master’s, had a clear idea where he wanted to take Black Badger, and hasn’t looked back since.

“I discovered that I’d rather be shivering standing outside in the cold than being warm but suffocated by everyone else inside. That inspired me to try and make something serious about Black Badger.”

Thompson got the idea of making high-tech rings from carbon fibre and titanium from his engineer father. In Canada, engineers receive an iron ring upon graduation, and Thompson thought to make one suitable for a pretentious design graduate (himself) just for fun. As it turned out, it was fun… and many others thought the same thing.

The idea of working with solid lume came from a knife maker friend who occasionally used solid lume in his knife handles because it looked cool. He suggested that Thompson try it in his carbon fibre rings. The latter’s reply was, “No thanks, my clients aren’t teenage ravers”. But Thompson made a glowing ring for fun, the concept took off, and now glowing rings constitute Black Badger’s most popular item.

Thompson has long been an aficionado of fast cars and contemporary horology and with his outsider pirate attitude has found collaborating with MB&F on the HMX Black Badger project a match of like minds.

L’Épée 1839 – the premier clock manufacture in Switzerland

For more than 175 years, L’Epée has been at the forefront of clock making. Today, it is the only specialised manufacture in Switzerland dedicated to making high-end clocks. L’Epée was founded in 1839, by Auguste L’Epée, who set up the business near Besançon, France to make music box and watch components.

From 1850 onward, the manufacture became a leading light in the production of ‘platform’ escapements, creating regulators especially for alarm clocks, table clocks and musical watches. By 1877, it was making 24,000 platform escapements annually. The manufacture became a well-known specialist owning a large number of patents on special escapements such as anti-knocking, auto-starting and constant-force escapements and the chief supplier of escapements to several celebrated watchmakers of the day. L’Epée has won a number of gold awards at international exhibitions.

During the twentieth century, L’Epée owed much of its reputation to its superlative carriage clocks and, for many, L’Epée was the clock of the influential and powerful; it was also the gift of choice by French government officials to elite guests. In 1976 when the Concorde supersonic aircraft entered commercial service, L’Epée wall clocks were chosen to furnish the cabins, providing passengers with visual feedback of the time. In 1994, L’Epée showed its thirst for a challenge when it built the world’s biggest clock with compensated pendulum, the Giant Regulator. At 2.2 m high, it weighs 1.2 tons – the mechanical movement alone weighs 120 kg – and required 2,800 man-hours of work.

L’Epée is now based in Delémont in the Swiss Jura Mountains. Under the guidance of CEO Arnaud Nicolas, L’Epée 1839 has developed an exceptional table clock collection, encompassing a range of sophisticated classic carriage clocks, contemporary design clocks (Le Duel) and avant-garde, minimalist clocks (La Tour). L’Epée clocks feature complications including retrograde seconds, power reserve indicators, perpetual calendars, tourbillons and striking mechanisms – all designed and manufactured in-house. Ultra-long power reserves have become a signature of the brand as well as superlative fine finishing.

MB&F – Genesis of a Concept Laboratory

10 years old, 11 calibres, countless highs, boundless creativity

In 2015, MB&F celebrated its 10th anniversary – and what a decade it has been for the world’s first ever horological concept laboratory: 10 years of hyper-creativity; 11 remarkable calibres forming the base of the critically acclaimed Horological Machines and Legacy Machines for which MB&F has become renowned.

After 15 years managing prestigious watch brands, Maximilian Büsser resigned from his Managing Director position at Harry Winston in 2005 to create MB&F – Maximilian Büsser & Friends. MB&F is an artistic and micro-engineering laboratory dedicated to designing and crafting small series of radical concept watches by bringing together talented horological professionals that Büsser both respects and enjoys working with.

In 2007, MB&F unveiled its first Horological Machine, HM1. HM1’s sculptured, three-dimensional case and beautifully finished engine (movement) set the standard for the idiosyncratic Horological Machines that have followed: HM2, HM3, HM4, HM5, HM6 and HMX – all Machines that tell the time, rather than Machines to tell the time.

In 2011, MB&F launched its round-cased Legacy Machine collection. These more classical pieces – classical for MB&F, that is – pay tribute to nineteenth-century watchmaking excellence by reinterpreting complications from the great horological innovators of yesteryear to create contemporary objets d’art. LM1 and LM2 were followed by LM101, the first MB&F Machine to feature a movement developed entirely in-house. The year 2015 saw the launch of Legacy Machine Perpetual featuring a fully integrated perpetual calendar. MB&F generally alternates between launching contemporary, resolutely unconventional Horological Machines and historically inspired Legacy Machines.

As well as Horological and Legacy Machines, MB&F has created space age Music Machines (1,2 and 3) in collaboration with Reuge; unusual clocks in the form of a space station (Starfleet Machine) and a spider (Arachnophobia); as well as two robot clocks (Melchior and Sherman).

And there have been distinguished accolades reminding us of the innovative nature of MB&F’s journey so far. To name a few, at the Grand Prix d’Horlogerie de Genève in 2012, MB&F was awarded the Public Prize (voted for by horology fans) and the Best Men’s Watch Prize (voted for by the professional jury) for Legacy Machine No.1. At the 2010 Grand Prix d’Horlogerie de Genève, MB&F won Best Concept and Design Watch for the HM4 Thunderbolt. In 2015 MB&F received a Red Dot: Best of the Best award – the top prize at the international Red Dot Awards – for the HM6 Space Pirate.